Products of industry

1. pulp industry

2. sludge

3. textile

4. technical textiles

5. special belts

6. Papermaking

The pulp and paper industrybasically comprise of companies that use wood as raw material and produce pulp, paper, board and other allied cellulose-based products.Papermaking, technical textiles and special belt making are major industries. These are the industries that feed the other industries to produce capital and other goods for domestic use.

Pulp is a lignocellulose fibrous material produced by separating cellulose fibres from wood, fibre crops or waste paper. Wood serves as about 90 % of the raw material for pulp industry with the remaining originating fromother plants. Pulp is most commonly used as raw material in papermaking, but it is utilised by the textiles, food, pharmaceutical and many other industries too.

Paper-makingcan be traced back to China about 105 BC, when paper was made using mulberry and other fibrescombining them with fishnets, old rags, and hemp waste. Modern papermaking industry has become much more organised and scientific with several sections, roughly corresponding to the processes traditionally involved in making paper. Pulp is refined and mixed in water with other additives to make a pulp slurry. The pulp slurry is distributedon a moving continuous screen and water is drained from the slurry. The wet paper sheet is compressed, dried and rolled.

Everypapermaking and pulp industry generates several distinct types of residues the main beingsludge which refers to the residual, semi-solid material left from the production processes. .Primary sludge is primarily cellulose fibre. Secondary sludge is comprisesmany materials that have undergone some degree of microbial decomposition. Pulp rejects are actually any woody material that fails to pulp in the digester. Generally, the quality of paper is measured by its non-wood-pulp content.

A Technical textile is a textile product that is manufactured for non-domestic purposes and is used by a large and growing number of other industries.

Technical textilesare used for automotive applications, medical textiles (e.g., implants), geotextiles (reinforcement of embankments), agro textiles (textiles for crop protection), and protective clothing (e.g., heat and radiation protection for fire fighter clothing, molten metal protection for welders, stab protection and bulletproof vests, and spacesuits). However, these are just a few uses, the use and demand for technical textiles is growing at a fast pace of about 4% per year greater than the growth of home and apparel textiles.For industrial applications as well as power transmission, technical textiles are used in special belts such as conveyor belts. Special belts are made of a fabric called “Carcass” which is responsible for the strength and stretch properties of the belt. Likewise, many such textiles are utilised for their enduring properties by different industries.

Source :- http://www.articlesbase.com/industrial-articles/products-of-industry-6734408.html

A glance at Papermaking and Technical textiles

The growth of industrialization and technology have brought about a paradigm shift in the character of industries as well as methods and means of conducting business in the new global meta-market. There has been great demand and growth in the domain of specialty fibers, forming fabrics, pulp and papermaking and technical textiles.

In addition to this,textiles are different from regular textiles as they are made of the materials and products intended for end-uses with different needs and the fabrics are selected principally for its performance and properties as opposed to its aesthetic or decorative characteristics. The advent of new technology such as special weaving process, nonwoven technique etc has enabled the manufacture of technical textiles.

The recent developments in industrialization have demanded technical textiles to be:

• High resistance to temperature

• Stable under stress and strain

• Fairly strong to absorb impact of highly reactive chemicals etc.

Coming to paper making, it is widely known that paper is made from pulp. However, the pulp can be procured from different sources. The first step is to remove bark from tree stems before processing. Depending on the tree species, the bark may be removed manually in the forests or mechanically in the pulp mill. There are two types of pulping processes:

1. 1. Mechanical pulping.

2. 2. Chemical pulping

Paper made from chemical pulp (i.e. containing little or no mechanical pulp) is often called wood-free paper. The pulp so obtained in brown in color and is bleached to obtain the white paper, as we know. There are many techniques of bleaching that may vary from mill to mill and also the process/sequence being used.

Bleaching is a multi-stage process and chemicals such as chlorine dioxide, oxygen, ozone and hydrogen peroxide are used in combination through different stages. One of the last stages of papermaking is the conversion phase where Paper is made using a specially designed paper machine, which creates a continuous uniform sheet of paper, board or tissue wound together. Most pulp and paper making firms generate several distinct types of residues such as organic wastes that are generated during wastewater treatment and/ or cleaning and Inorganic wastes that are generated during the process and chemical recovery process. One organic residue is sludge that is mainly cellulose Fiber. Secondary sludge includes a variety of materials that have undergone some degree of microbial decomposition.

Talking of industrial use special belts there are different kinds of special belts to suit specific purposes. A basic conveyor belt is a long continuously moving band of rubber, technical textile, or metal, used in a place such as a factory, warehouse or airport to transport hefty freight from one place to another: One type of special belts is woven conveyor belt which is made up of multiple layers of fabrics woven into one piece, Stripes are woven into the belt to indicate the number of plies. Generally the piles range from 2 to 10. Spiral conveyors are more subtle like and suit other specific business needs.

Technology has vastly assisted in the development of more specific industrial products and process to increase utility of machines and reduce wastage.

Author is an online marketer and loves to write on different subjects. With this post he is sharing information on conveyor belts & technical textiles in Jaipur, Rajasthan.

Source :- http://www.zimbio.com/Industry/articles/uwsgsegYM1P/glance+Papermaking+Technical+textiles?add=True

Paper Making & Machine Clothing

There is adiversified range of products that encompass our life. Such products are not only indispensible but may also constitute the very basis of our day-to-day survival and functioning. Paper and paper products are widely used in our daily life and it’s hard to deny their immense worth and utility. From writing, to reading, to […]

Wires & Fabriks (S.A) Ltd – History

Wires & Fabriks (S.A) Ltd commenced operations in 1963 at Jaipur, India with the manufacture of Bronze wire cloth then used on fourdrinier paper machines. The company became a public limited company in 1985.

In 1983, Synthetic Forming Fabrics (in Single Layer) were introduced. As a progressively oriented company we soon pioneered the introduction of Double Layer Fabrics followed by Triple layer fabrics.

Woven Dryer Screens with Flat Warp were introduced in 2001 and Spiral Link Dryer Screens in 2005.

Today, we offer a full range of

Forming Fabrics: In Single Layer, Double Layer and Triple Layer (Triple Weft as well as SSB range)

Woven Dryer Screens: in a wide permeability range for all paper machine positions and speeds.

Spiral Dryer Screens: with & without stuffing for all paper grades and ETP plants.

Pulp Fabrics: In different designs and materials (Polyester/Polyamide/Kynar/Anti-static/Combinations)

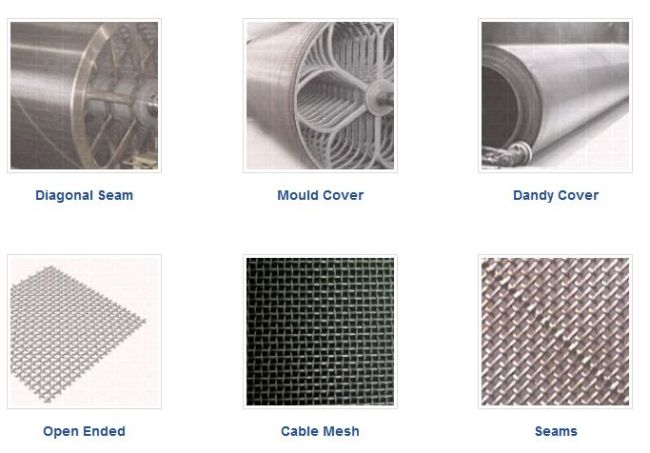

Stainless Steel Mesh: In Open ended and Diagonal Seam form.(in a wide mesh range of 2-80/cm).

Phosphor Bronze Mesh: In Open ended and Diagonal Seam form.(in a wide mesh range of 2-14/cm).

In 2009 and 2010, we invested over US$ 12 million in modernizing, balancing and enhancing our capacity with the most modern warping machines, wide weaving looms and automated seaming machines. As a result, today we are well equipped to offer the most modern SSB Forming Fabric designs for Fourdrinier/Twin Wire Formers/Gap formers/Multi formers etc .

Source :- http://www.wirefabrik.com/

Recent Comments